You met the DeskJet, now meet the DrugJet

Printing drugs, Felix could be about to make a lot of money

Everyone has heard of the inkjet printer, you probably have one yourself. However, one application of the venerable office supply you haven’t heard of is printing drugs, recently developed at the UCL School of Pharmacy.

An inkjet printer works by delivering small droplets of ink onto the page, controlled via an electrical signal. In most inkjet printers a thermal technique is used: heat is used to vapourize ink, which is then delivered onto the page and dried. A mixture of the colours (and black) are used to produce the desired output on page.

In this development, the same thermal process has been used to deliver the drug carbamazepine, a medication often prescribed topeople suffering from epilepsy.

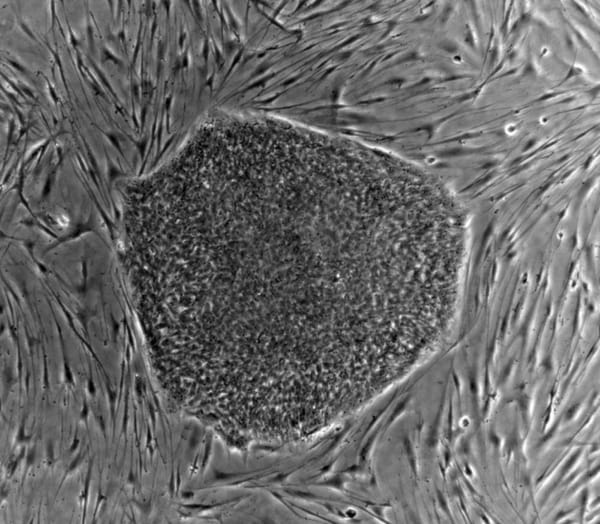

The original synthetic method for this drug involves delivery of a tiny amount of the drug. When deposited, the drug evaporates and crystallises almost immediately, producing the desired compound. In this new technique, the same method is used, but an inkjet printer is used to precisely control drug delivery. This makes use of the fine control that inkjet cartridges have when deploying ink, with many inkjet printers capable of printing to 1,200 dpi.

The main advantage of using printers is their ease of conversion to printing drugs, which also has the desirable quality of being cheap to do. A good quantity of crystallisation has also been reported, with even better yields being achieved when multiple passes have been used.

This development is not completely without its flaws, however, with certain solvents having the potential to wreck havoc with the cartridge material. Common solvents used, water and water/ethanol mixtures, are fine, however other commonly used solvents may cause more trouble.

DOI: 10.1039/c2ce26519b