Shell We Innovate?

Sea shells aren’t just waste or decoration: from biomaterials to construction, they offer serious opportunities in sustainability and innovation.

You might have spent part of the summer by the sea and picked up a shell or two on the beach, shoved it into your pocket and, back home, placed it in a bookshelf to remember that warm, sunny summer day once the gloominess of autumn rolls back in. But did you know that shells (from sea or land animals) could help us regrow bones and reduce CO2 emissions?

Beyond jewellery and decorations, there are so much more applications to waste shells. Shells have similar properties to limestone, with high calcium carbonate content (98%) and traces of other minerals. Limestone mining is damaging to the environment and, during the calcination process, produces up to 0.75 tonne CO2 per tonne of limestone. On the contrary, shells are renewable and cheap, which makes them a great alternative to limestone. In addition, there is an abundance of shell waste: the consumption of snails, oysters, eggs, sea urchins, scallops, mussels and more leads to millions of tonnes of shell waste to accumulate yearly.

When unmanaged, this lead to land and air pollution when the waste decomposes. This creates an unpleasant odour and attracts flies, and poses a serious health hazard. Hence, incorporating waste shells in industrial applications would not only help us reduce CO2 emissions but also benefit populations.

According to researchers from the University of Birmingham, the applications of waste shells are numerous. They can be used to provide livestock with calcium supplements, help regulate soil acidity for agriculture, become concrete aggregate, be turned into ceramic, cement or synthetic stone, be used as biofilters in water treatment, catalyst, and even be employed in hydroxyapatite (HA) production.

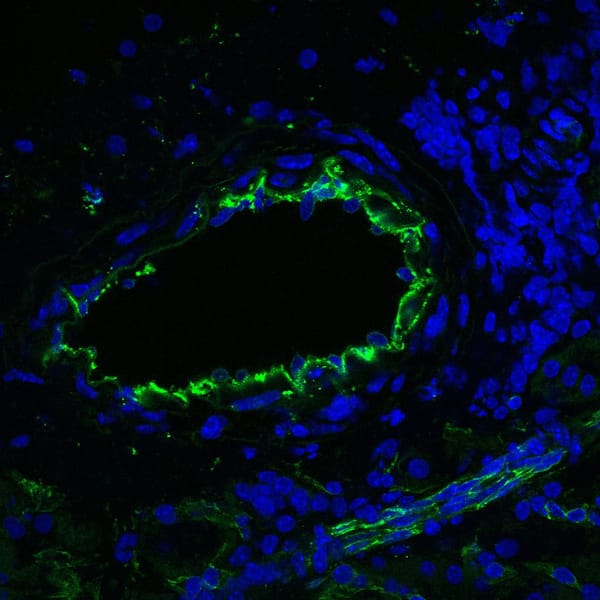

HA is the main mineral component of human bones and is thus employed as a bone substitute and in bone grafts. Traditionally, HA is produced either through pure chemicals or is derived from human, animal or fish bones. In a 2013 paper, researchers from Turkish universities proved that using biogenic calcium carbonate and converting it to HA with a mechano-chemical (ultrasonic) method was possible. Given the importance of HA, the proof that shell waste has strong, and affordable, biomedical applications is great news. As stated previously, the biomedical application is one of many. In an article published in June 2024 by the Journal of the Australian Ceramics Society, it is shown that snail shells can be an alternative to calcite raw material from which wall tiles are made. They become a low cost, eco-friendly and similar-in-properties solution to prevent limestone depletion. Similarly, in 2021, Mexican researchers created various ceramic compounds using a powder with sea snail shells and cuprite. This process was feasible with an in-situ chemical process in a solid state and reported a short synthesizing time. The use of cuprite allowed for enhanced properties, making these ceramics more suitable for harsh conditions.

Hence, these could go on to have, for example, biomedical applications (bone-grafts, dentistry, etc) or applications in humid climates. A limitation (is it really a setback if it encourages us to research more into this?) was however found: a low fracture toughness that made these ceramics brittle.

Another major use for shell is in construction, as mentioned earlier. In a publication dating March 2025, scientists explored how shell waste could be used to reinforce unstable soils, notably expansive clay soils. Soil safety is essential to prevent landslides, flooding, to protect property and lives and more. When faced with unstable soils, there are typically two options: soil replacement or soil reinforcement. Soil replacement is costly as it requires excavations and the disposal of unsuitable soil for example, and soil reinforcement is chemical (cement, fly ash, etc.) which harms the environment and are expensive to make. Adding shells is in a sense soil improvement: these added shells improve soil structure, but also improve nutrient retention, and water infiltration by reducing erosion and soil degradation and preserve biodiversity. This option is also the most cost-effective. Using shell waste offers two other advantages. Shells are rich in calcium oxide as well as other compounds such as silicon dioxide which enhance the soil. In addition, there is plenty of shell waste and most of it poorly disposed due to its volume, recycling these shells in soil improvement is thus environmentally sustainable.

As these shells are collected post-mortem, this does not lead to further sustainability issues and, provided the conversion from calcium carbonate to calcite is done in a low carbon footprint way as done in the papers stated above, shells have the potential to revolutionize green technology and engineering. With applications ranging from the biomedical field to construction, these oncediscarded materials are no longer ‘just waste’, they are now resources for a sustainable and innovative future.