Engineering the Hyperloop prototype

Osama Awara discusses the challenges behind the high speed transport system

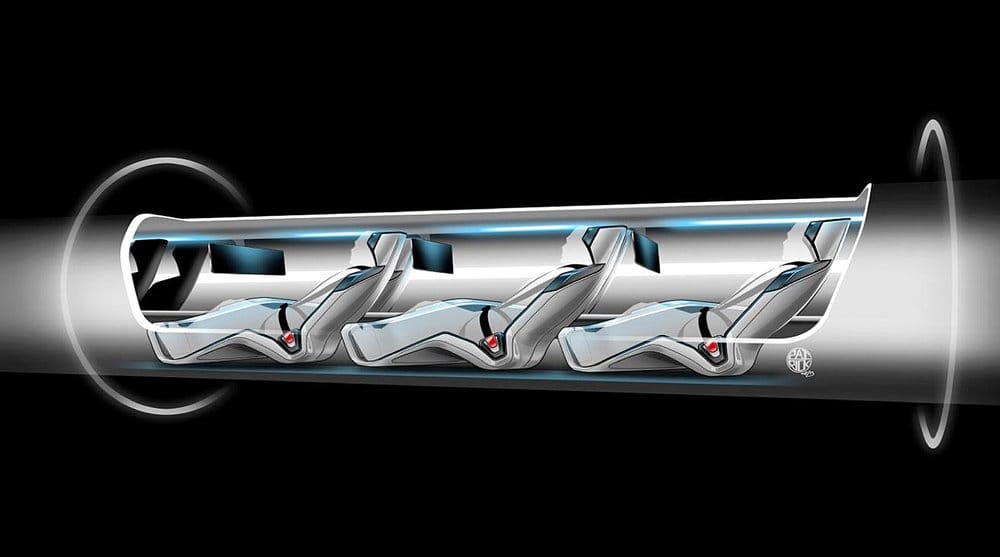

It was in 2012 that the restless entrepreneur Elon Musk first announced his idea for a high speed transport system – the Hyperloop. Described by the magnate as ‘a cross between a Concorde, a railgun and an air hockey-table,’ this next-generation train system aims to transport people at speeds of over 700 mph. This would mean a journey from London to Edinburgh would take half an hour, faster than a jumbo jet while at the same time avoiding all those airport waiting times.

Initially, Musk released his ideas and plans of the Hyperloop for other entrepreneurs and engineers to take up the task of designing and building this feat. Eighteen months have passed, and now Musk has announced on Twitter that he will build a Hyperloop prototype in Texas. Clearly he has grown impatient, which begs the question: how exactly will this prototype be made?

The Hyperloop being built is for test purposes only and not an actual useable transport system. It is to encourage other companies and students to come up with the pod designs themselves. For a second time, Musk is trying to give people a piece of the pie.

One of the greatest challenges is designing the Hyperloop so that it can reach such high speeds. This means that the biggest threat to the speed of any mobile pod or carriage is friction. Classical train systems experience high levels of resistance due to the contact of the train wheels with rail tracks.

The Hyperloop aims to avoid this by having the pods floating in the air by magnetic levitation, similar to the Shanghai maglev trains in China. Part of engineering is observing; if an engineer can create something new out of existing creations, then he is a good observer. However, the difference comes with the introduction of air bearings.

The air bearings allow the pod to levitate while at the same time the pod will force air from the front of the pod to the rear through holes, using similar techniques to the well-known air-hockey game – an existing creation.

One issue that arises is that when the capsule is travelling at high speeds, if its cross-section fills too much of the tube, the air won’t have the time or space to travel around the capsule. This would lead to a build-up of air at the front of the capsule – an undesired effect called choked flow. Choked flow leads to huge amounts of friction that would prevent the capsules reaching such high speeds.

A proposed solution to this is to use an air compressor, which will pump air from the front through a nozzle to the rear. This essentially creates a vacuum space at the front of the capsule, reducing the pressure in the tube and hence the resistance.

When objects travel at high speeds, it is necessary to avoid bends and inclines in order to ensure that there are minimal excessive G-forces acting on the passengers.

Experiencing an excessive G-force could make the journey a danger to health, let alone a very uncomfortable ride. With this, the Hyperloop tube that connects one city to another must be kept straight, which for obvious geographical reasons would be difficult to achieve. Texas was chosen to locate the test track for this reason, as the amount of free space there is more than anyone can ask for a Hyperloop test playground.

Careful urban planning would be required to practically build a Hyperloop tube linking one city to another, which may potentially pose the biggest challenge to a successful infrastructure.

The test track is certainly one big step forward to the development of the Hyperloop. It is up to big companies, researchers and even students to bring forward ideas and build designs of pods to be used in the rail system of this grand design.

It would be very interesting to see what proposals are brought forward and how they would fare against one another, it is usually the simplest of designs that fare the best.